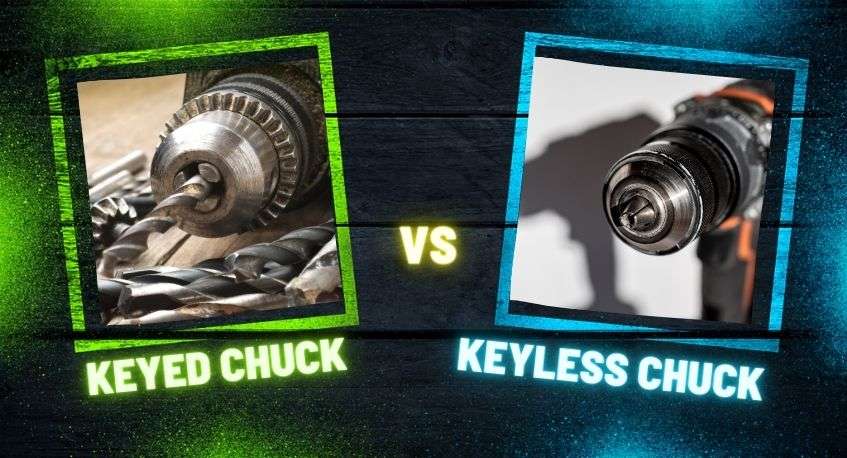

From an industrial operator to a layman at home, a drill machine is required to make precise holes in walls, ceilings, floors, or any desired object. The selection of the drill machine and bit is what most people do, but have you thought about the chucks? They are the jaws of a drill machine that hold bits to make precise holes. If you select the right type, you will be on your way to having accurate results. Let’s not waste any time and move straight to the main topic. If you want to know which type of chuck is better for your task, here is a comparison that can help you.

It is a classic mode of drill chuck where a tiny key is required to insert and remove drill bits. Users have to use a key to open the chuck’s mouth, place the drill bit, and then tighten it back. If you lose this key, you will be unable to use this type of chuck. Therefore, it relies on a key for inserting the drill bit. Of course, it takes time for bits’ insertion because operators have to twist the key until it opens or closes the chuck.

This one is a simpler type with no key at all. All it needs is a direct twisting of the chuck with a hand to open and close it. Instead of a key, users can simply open it, place the bit, and close it back without any reliance on a key. It works well on various surfaces without risk, except when used on metallic or concrete surfaces. A keyless chuck does not provide as strong support as a keyed one does against vibrations and extremely tough surfaces.

Here's an In-depth guide on how keyless drill chucks work

Let’s compare these drill chucks to get a clear view of their performance. Then we can determine which one is better under which condition. Of course, both types have their pros and cons, which we will discuss below.

A keyed type needs a small gear key to open and close the mouth chuck. You must not lose it because the drill machine depends on it. Besides, a keyless chuck only needs a bare hand to be opened and closed for the bit’s insertion. Just hold it tight and twist to open and close it.

A keyed chuck has a better grip than a keyless one. The reason is that the key tightens the bit inside the chuck, which shows a strong mechanism of the keyed chuck. The bit remains stable inside without any vibration or risk of losing out.

Since a keyed chuck has a more secure grip, it can make a bit stay on the path without any risk of collapse. Therefore, a keyed chuck is more compatible with tough surfaces, such as metal and concrete. If you are working on a plastic or wood surface, a keyless chuck will be a good choice.

The accuracy level is better in a keyed chuck due to its secure placement. A key tightens the chuck’s internal lock to hold the bit firm. As a result, the accuracy level improves over that of a keyless type.

A keyed chuck is safer than a keyless one. Since a user must tighten the chuck on a keyless type, there could be errors in the insertion and closing process. However, both types provide a safe result in general use.

Since the keyless chuck is a newer version and more user-friendly, its cost is slightly higher than that of the other one.

I have curated a list of 13 Key features a high-quality drill chuck should have.

Here are some technical comparisons to further clarify the details. You can gain a better understanding when you are familiar with this part.

The lower the vibrations and sounds in the chuck, the better its runout tolerance will be. A keyed chuck has low runout tolerance, which means there is less vibration, sound, and wobbling during the drilling operation. It gives the keyed chuck the upper hand in the comparison.

A keyed chuck has a better grip, which means it has better torque capacity. The chances of accidents like a bit collapsing are less in this type because of its higher torque capacity. The bit remains secure and withstands maximum challenges before breaking or being compromised.

There are various sizes of chucks, but some are ideal for specific surfaces. A keyed type with a 1/2-inch diameter is suitable for metal and concrete surfaces. A keyless type of 1/4-inch is perfect for plastic and wood surfaces. Likewise, a larger chuck size can better control larger bits. If you need to make small drilling holes, you will need smaller chucks.

Here's how to choose the perfect drill chuck size Guide.

Some mounting standards are followed in the drill machine chucks industry. These standards aid in selecting the correct chuck for the appropriate type of bit and drilling. The precision comes when users follow these standards. Their codes are listed below:

It depends on the material you are drilling into. Then, the efficiency, grip, and various factors you have read about will help you make a decision. Deciding between a keyed and a keyless chuck will extend beyond just examining the insertion process.

The primary difference between a keyed and keyless chuck lies in the insertion process. One requires a key, while the other can be controlled with bare hands. However, the precision, grip, and control are better in a keyed chuck. Besides this upper hand, a keyed chuck is mainly preferred by experts. A typical user or layman goes for a keyless drill for general drilling.

A keyless chuck has less grip than a keyed one. Moreover, the accuracy and grip are lower in it as compared to the keyed one.

Because keyed chucks are more reliable, precise, and durable, they can hold bits more firmly than keyless types.

If the drill machine is compatible with the keyless chuck, you can replace the keyed one with a keyless type. You will need to consider the arbor size and various other factors to select the correct keyless chuck for your drill machine.

Use your hand to tighten the chuck properly, and then ensure it is well secured. It depends on the optimum force your hand can generate without damaging its gears.

Looking for top-quality keyless chucks for your drill press? Discover where to find the most reliable and durable options trusted by professionals. Read this guide to explore the best places to buy keyless chucks.

Advantages of purchasing drill chucks from a Chinese supplier